Celebrating Milestones of Our Members

The National Hardwood Lumber Association stands as a beacon of tradition and excellence in the hardwood lumber industry. This month, we turn the spotlight on the remarkable contributions of our members. These members have not only shaped the fabric of our industry with their steadfast dedication and innovative practices but have also forged paths that will guide future generations.

Nestled within North Central Pennsylvania’s renowned hardwood timberlands, Patterson Lumber Co., Inc. stands as a testament to enduring commitment, celebrating 75 years of continuous membership. This remarkable anniversary reflects a legacy of quality, resilience, and leadership in the forestry industry.

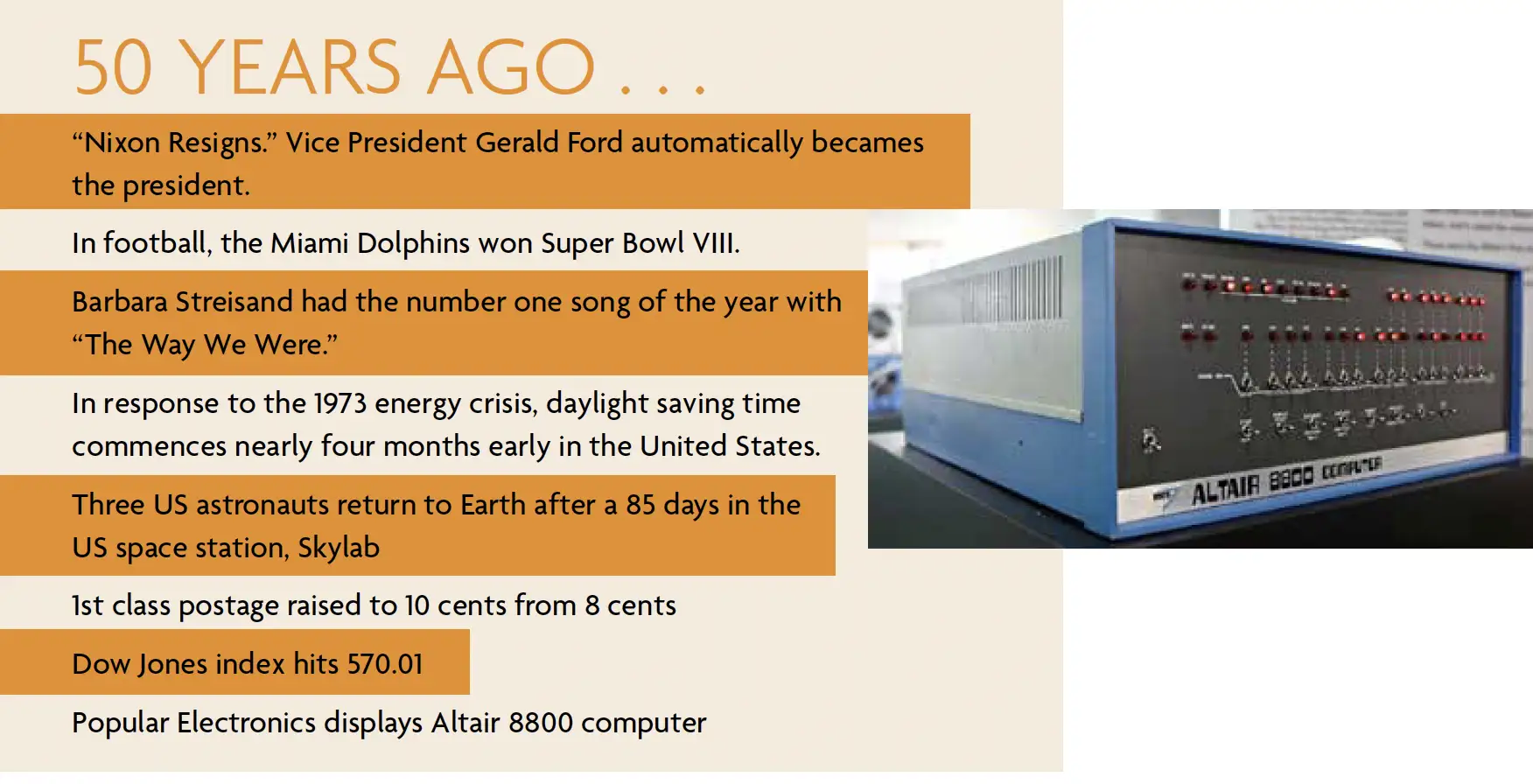

Equally noteworthy is the golden jubilee of membership for several other key players within the NHLA community. American Woodmark Corporation, known for its innovation in cabinet manufacturing; Corley Manufacturing, a stalwart in sawmill machinery; McDonough Manufacturing Co., which has consistently set industry standards for sawmill equipment; Sirianni Hardwoods Inc., a family-run business distinguished by its dedication to quality lumber production; and USNR, a leader in technology and manufacturing solutions for the wood products sector, all celebrate 50 years of unwavering membership.

These milestones are not just marks of time but are testaments to the commitment, innovation, and community that are hallmarks of the NHLA. As we reflect on their histories, we are inspired by their stories of growth, adaptation, and success. Join us as we honor these members, whose dedication not only strengthens our association but also propels the entire hardwood lumber industry forward.

June 1949

Patterson Lumber Co., Inc.

This all began in 1921 with a partnership between F.L. Patterson and D.W. Frazee. These two men operated a mangle roller bobbin manufacturing facility in Wellsboro, Pennsylvania. In 1924 Patterson bought out Frazee. By 1927 the original bobbin-manufacturing plant was joined by a mill in Galeton and in Friendship, New York. Even though the bobbin export decreased in the 1930s, the Wellsboro sawmill continued. In 1936 a retail building materials department was added in Wellsboro and then in 1948 the business was incorporated and Paterson Lumber Co., Inc. was formed. Now a fourth-generation, family-run sawmill, Patterson Lumber Co., Inc. employs the latest technological advancements to increase production and eliminate waste, while further increasing safety and lumber quality.

January 1974

American Woodmark

It all started when a Long Island-based dentist, Alvin Goldhush, saw an opportunity to create cabinets for his dentistry business. He founded a company called Raygold Industries. Raygold had a sales volumes of about $6 million and was acquired by Boise Cascade in April 1971. Four executives from Boise Cascade’s cabinet division leveraged a buyout and purchased the company. American Woodmark Corporation is formed with over 1,100 team members and had 3 manufacturing facilities. Over the years, American Woodmark developed successful relationships with two big-box retailers Home-Depot and Lowe’s. This is when they moved their corporate headquarters to Winchester, Virginia. Today, they are one of the three largest cabinet makers in the country and are a trusted partner to their customer and communities.

February

USNR

USNR’s history dates to the 1850s, and since then it has brought together a multitude of designs, technologies, and talents. Starting as a small sawmill equipment vendor, USNR is now the world’s largest supplier of equipment and technologies for the wood processing in-dustry. With hundreds of patents to its credit, USNR has continually pushed the industry forward with investment and innovation. They are best known for providing end-to-end solutions for sawmills and planer mills, including log lines, curve sawing gangs, edger lines, trim-sort-stack systems, dry kilns, and the optimization and control technologies that maximize the output and performance of that equipment. Today, USNR operates four facilities in the US, three in Canada, and two in Sweden. They also maintain additional local-language sales, service, and aftermarket support centers in Norway, Finland, Russia, Estonia, Poland, and Germany.

Since 1898, the NHLA has been an important resource for setting grade standards, learning about the needs of hardwood mills, and sharing the technological advances that are being made to provide efficient solutions for hardwood mills which has contributed to great success for USNR over the last 50 years of membership between the two.

Like most, 50 years ago, mechanical equipment was the driver of USNRs’ business. Control systems and PLCs were the norm of early computing but as the world was progressing, so was technology. Scanning and optimization systems started to come online in the late 1980s which brough automation and efficiency to the process but it wasn’t until the 1990s that USNR started to focus on solutions specifically for the hardwood industry. Today, they are focused on providing the full solution for their customers. With mechanical systems, control systems and scanning, optimization, and grading- these were all designed for the special needs of the hardwood industry. Areas like grading, SAM (self-adjusting machines) and leading-edge HMI’s (human machine interfaces) converge has shaped a new era of wood processing technology. USNR thrives on innovation, constantly evolving to enhance efficiency, safety, and productivity. With hundreds of patents, they continue to drive the industry forward through investment and innovation and integrating cutting-edge solutions into its product lines. Technology has propelled USNR into a dynamic era, where agility, connectivity, and innovation define its business and landscape.

With all the years of membership, USNR’s takeaway is, thanks to the NHLA, the strength of the group outweighs the individual strengths of the members. USNR is proud to be a participating member of the NHLA.

April 1974

Sirianni Hardwoods, Inc.

Sirianni Hardwoods, Inc. is in Painted Post, New York, in the heart of the Northern Appalachian hardwood producing region. The company was founded in 1979 and is operated by the Sirianni family. They have been in the hardwood business for four generations. Sirianni Hardwoods specializes in kiln dried Red Oak and White Oak lumber and supplies prime hardwood lumber to manufacturers and distribution yards throughout North America and in the export markets.

August

Corley Manufacturing Co.

For over 100 years, Corley has supplied rugged, up-to-date, dependable machinery to the sawmill industry and has backed it up with fast reliable service. Since 1905 they have focused their efforts exclusively serve sawmillers. By doing so, this has enabled Corley to develop sawmill machinery that is uniquely suited to the sawmillers needs. Corley carries on this tradition today with their skilled and experienced team of engineers, service technicians, sales reps, production workers and management personnel.

August 1974

McDonough Manufacturing Co.

McDonough Manufacturing Co. is a family-owned and operated manufacturer of custom sawmill machinery, in business since 1888. They have focused on providing durable sawmill machinery, while providing the efficiency and speed required by the modern sawmill. McDonough buys steel and all parts, fabricates, CNC and manual machines, assembles tests and paints all their own machinery. They have had their first head office in the Chippewa Valley of Wisconsin since 1888 and have also recently expanded its operations internationally with a manufacturing facility in Mactaquac, NB, Canada that opened in October of 2017 along with the acquisition of BID Canada Ltd. in early 2023.

Membership with the NHLA holds a great deal of value for McDonough as it has provided a platform to connect and collaborate with industry peers. Throughout their last 50 years of membership with the NHLA, McDonough has gained invaluable partnerships while engaging with clients, expanded their network and enhanced their knowledge base. McDonough has not only strengthened as a company throughout this milestone membership, but they have also been fueled in their growth, in-novation, and success in the industry.

Technology may have changed over the last 50 years, but one thing that has remained the same since McDonough’s founding in 1888 has been their core values: honesty, integrity, and customer-centricity. The integration of technology has brought a new era of efficiency and sustainability which has reshaped the way that McDonough utilizes forest resources, which is ensuring the longevity of the industry. New-age technology has empowered McDonough to cater to the evolving needs of their customers by delivering high-quality products tailoring to their specific requests. McDonough has chosen to embrace the partnership between traditional values with technological innovation to ensure their stability but to also contribute to the resilience of the towns and regions who are dependent on sawmill operations so that the sawmill industry can continue to move forward.

Even as modern technology is revolutionizing the way McDonough conducts business, they still recog-nize and appreciate the amount of wisdom that the industry veterans have and share from their decades of experience. Throughout this 50-year membership, the NHLA has served as a spot for collective growth and advancement for McDonough.

Share:

Related News & Blog

November 5, 2025

November 5, 2025

Questions?

Have questions or need any assistance regarding the NHLA Annual Convention & Exhibit Showcase?