Hardwood’s Path to Growth: Leveraging Mass Timber Opportunities

Hardwood lumber is usually sold based on how it looks. That’s why it’s graded using the NHLA (National Hardwood Lumber Association) rules, which focus on appearance. Softwoods, like pine and spruce, are different. They’re graded based on mechanical properties (like strength and stiffness) because they’re primarily used in construction. These two systems use different grading criteria, but that difference could be an advantage.

Today, mass timber construction is growing fast in the U.S. and around the world. As builders seek strong, sustainable materials, hardwood stands out as an ideal solution.

WHAT IS MASS TIMBER?

Mass timber is a way of building with large, solid wood panels. A common product is CLT (cross-laminated timber), layers of wood glued together to make strong, stable panels. CLT is used to build homes, offices, and even tall buildings. To make CLT, manufacturers need wood in specific sizes, usually between 3/4 inch to 2 inches thick. Good news: hardwood mills already produce lumber in those thicknesses.

Then what is the challenge? Many hardwood boards don’t come in the standard widths and lengths used in construction. That means they must be trimmed and resized, wasting time, wood, and money.

A SIMPLE SOLUTION: CUT TO STANDARD SIZES

What if hardwood producers started cutting their boards to match the sizes used in softwood construction? They wouldn’t need to change how the wood is graded or processed; they would just need to adjust the width and length. This small change could make hardwood boards easier to use in mass timber products like CLT. Such a shift could unlock a substantial new market for hardwoods, especially for lower-grade lumber that doesn’t sell well for furniture or flooring.

CAN LOWER-GRADE HARDWOOD BE STRONG ENOUGH?

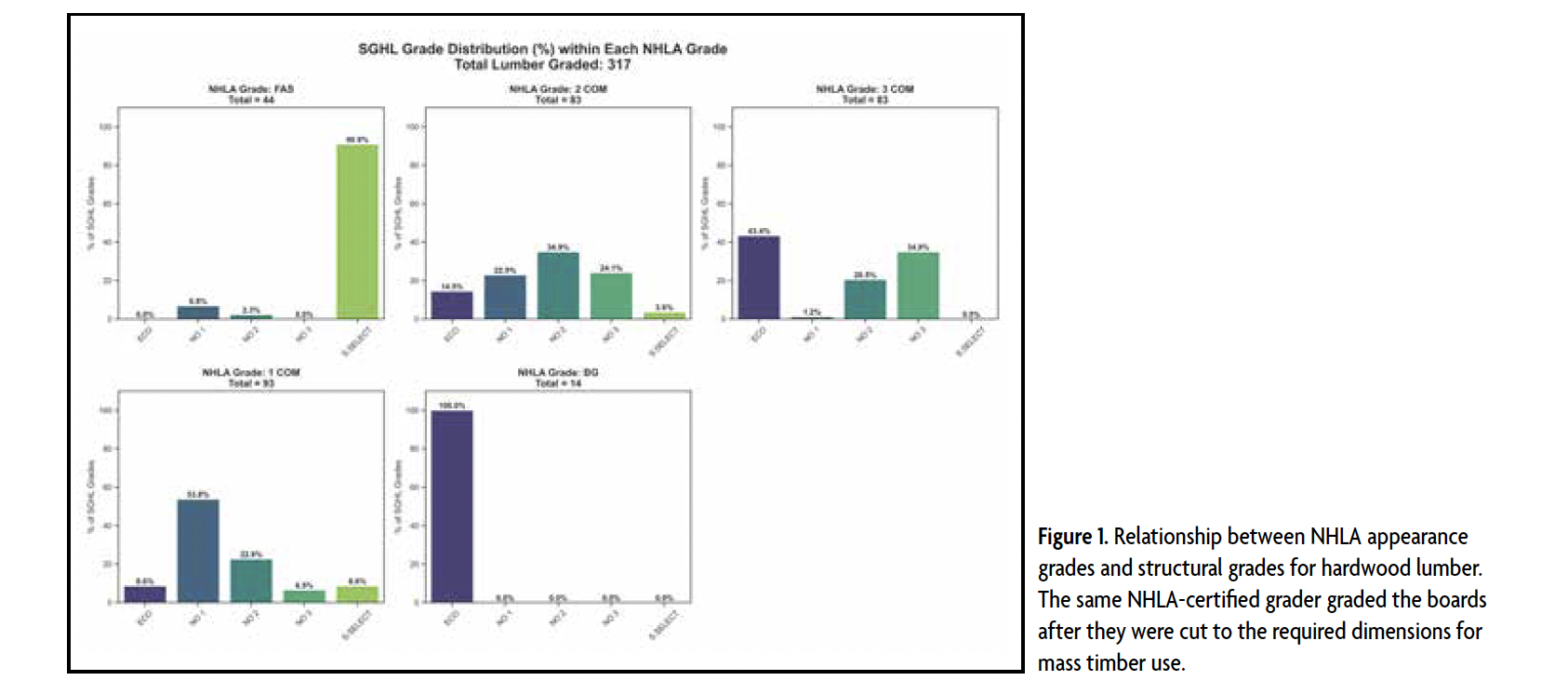

To find out, we worked with Virginia Tech to test whether lower-grade hardwood boards could meet structural standards. We took logs with one or no clear faces, produced lumber, dried them, and graded them using both grading rules to see how they related to each other. The result is shown in Figure 1. Our observation is that

The first structural application of yellow poplar CLT is Maggie’s Centre in Oldham, UK — the world’s first building made from hardwood cross-laminated timber. To learn more visit https://www.americanhardwood.org/en/examples/our-projects/maggies-oldham/material.

NHLA 2 Common and lower lumber make up a larger portion of the higher grade SGHL. This means a significant portion of hardwood lumber has the potential to support the construction of homes, schools, and other buildings as part of mass timber structures.

A MILESTONE: YELLOW POPLAR APPROVED FOR CLT

This idea isn’t just a theory; it’s already happening. The PRG 320 standard, which sets rules for making CLT, now includes Yellow Poplar as an approved species. It is the first hardwood species approved for the manufacture of CLT. This is a big step. It proves that hardwood can meet performance requirements for mass timber and opens the door for other species to follow.

WHAT HARDWOOD MILLS CAN DO NOW

Hardwood producers don’t need to make major changes. Here’s what you can start doing today:

- Reach out to the CLT mills near you and inform them that you can produce lumber that matches the specifications of their required raw materials.

- Cut lumber in 4/4, 6/4, or 8/4 thicknesses (already standard in many mills).

- Match the widths and lengths used in softwood construction.

- Keep using NHLA appearance grades, but market the wood for structural use as well, so that if you cannot make a deal, you can sell the lumber as NHLA grade.

TAKE ACTION – DON’T MISS THIS OPPORTUNITY

The future of hardwood is not just in furniture or flooring; it’s also in strong, sustainable, and versatile mass timber. By adjusting your cuts to standard construction sizes, you can unlock a major new market, sell more of your lower-grade lumber, and increase your profitability. Start today. Reach out to CLT manufacturers, cut to standard sizes, and ensure your hardwood products are ready for mass timber’s growing demand.

WHY THIS SHIFT IS A GAME CHANGER

Making this change brings benefits for everyone:

- Hardwood mills can sell more lumber, especially grades that need a new market.

- Mass timber manufacturers get a strong, local alternative to imported softwoods.

- Less wood fiber is wasted, which is better for the environment and efficient operation.

- The U.S. hardwood industry gets a new path for growth, with minimal cost or change.

THE BOTTOM LINE

The world is trying to move toward greener, wood-based construction. Hardwood has the strength, sustainability, and beauty to be part of that future, but only if it’s processed to meet the specifications of modern construction. Yellow Poplar has already proven it can work. Other research shows that many other species can, too. Now, it’s up to the hardwood industry to take the next step. By cutting boards to standard construction sizes, we can unlock new opportunities, reduce waste, and help build a more sustainable future.

Figure 1. Relationship between NHLA appearance grades and structural grades for hardwood lumber. The same NHLA-certified grader graded the boards after they were cut to the required dimensions for mass timber use.

By SAILESH ADHIKARI, NHLA Director of Research and Development

Share:

Related News & Blog

June 1, 2025

June 1, 2025

Questions?

Have questions or need any assistance regarding the NHLA Annual Convention & Exhibit Showcase?